The Secret of Car Design: Why Automakers Still Sculpt Full-Size Car Clay Models (Since the 1930s)

by AutoExpert | 11 November, 2025

The car industry changes constantly. Diesel was supposed to be the future, then everyone was gonna ditch gas engines entirely, and now half the big automakers are pumping the brakes on their EV plans. But some things just work, and in design studios across the country, they're still doing something that started back in the 1930s: sculpting full-size car clay models.

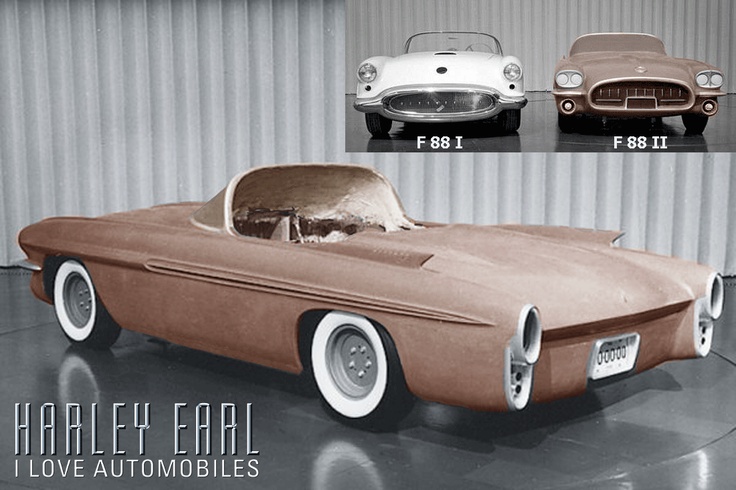

GM's Harley Earl came up with this almost a hundred years ago when designers were stuck using wood and metal, which made it pretty much impossible to nail those smooth art deco curves everyone wanted. You'd think computers would've killed clay modeling by now, but nope. Designers still prefer getting their hands dirty, and the reason's actually pretty straightforward.

A physical clay model just hits different. You can move it around, check it under different lighting, walk around it to see how the lines flow together, tweak whatever needs tweaking, even wrap it to look like the finished car. Almost every automaker on the planet still does this.

It's Way More Complicated Than It Looks

Just because the technique's old doesn't mean it's simple. Designs start on paper or a computer, and if the higher-ups like what they see, it gets approved for a full-size clay version.

They build it on something called an armature—basically an adjustable aluminum frame that acts as the wheelbase. Foam blocks and boxes go on top of that, then clay gets layered over everything. If the whole thing was solid clay, it'd weigh tons and nobody's moving that around.

The "clay" isn't even real clay—it's more like fancy plasticine that stays workable when kept warm. A five-axis milling machine carves the blob into something that looks like a car, then a team finishes it by hand.

These models can be adjusted on the fly, lit different ways, fitted with different wheels, painted different colors. It's how cars change so much between concept and what actually rolls off the assembly line. Designers get to see their work in real 3D form instead of just staring at a screen, and when guests visit, a full-size clay model's way more impressive than pulling up a rendering on a monitor.