Tesla's Panel Gap Problem: Has Elon's Quality Control Improved?

by AutoExpert | 28 May, 2025

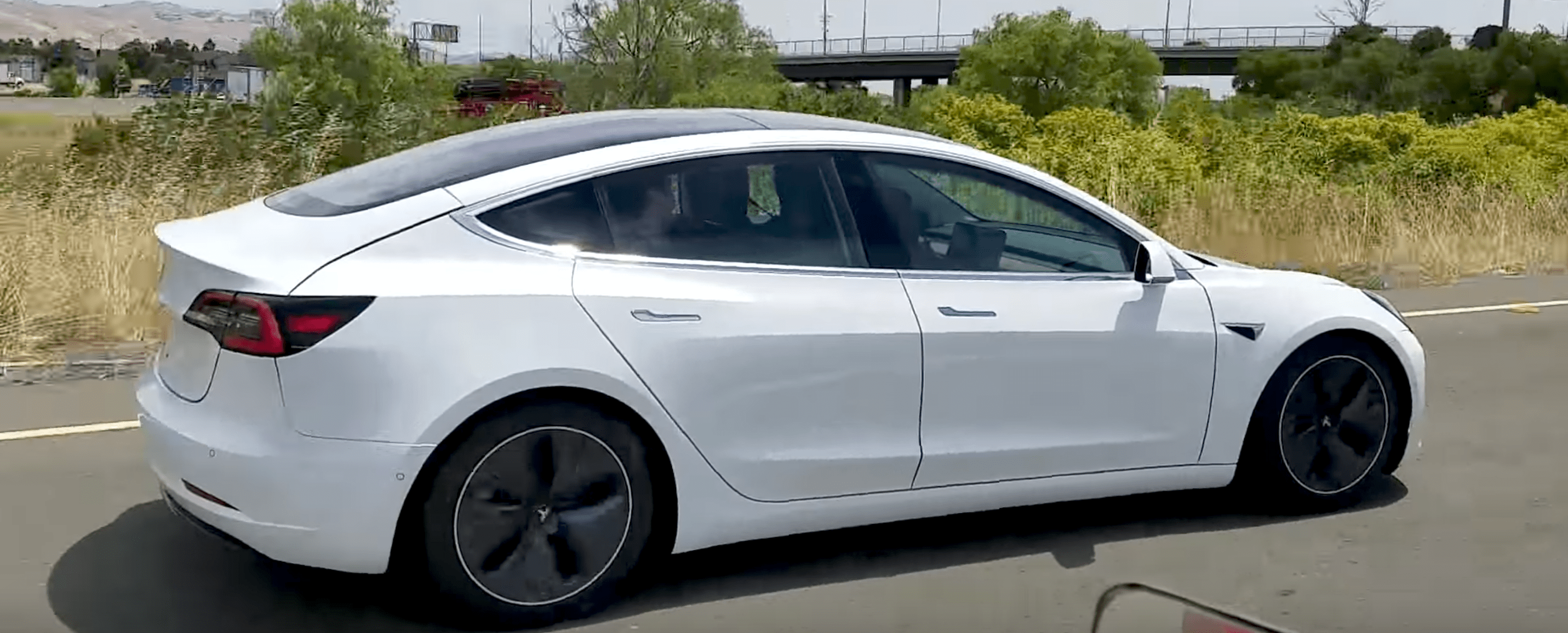

Tesla went from zero to EV kingpin faster than anyone thought possible, but their rapid rise came with some embarrassing growing pains. For years, people have been roasting Tesla's build quality - wonky panel gaps, misaligned trim pieces, and paint jobs that looked like they were done in someone's garage. The early Model S cars were pretty rough, and don't even get started on the first Model 3s rolling off the line.

Even Elon Musk admitted they had no clue what they were doing. Back in 2018, he straight-up told investors, "We were huge idiots and didn't know what we were doing" when it came to manufacturing the Model 3. At least he was honest about it.

Some Progress, But It's Complicated

Tesla has gotten better over the years, especially at their Shanghai factory. Cars built in China consistently get higher marks for build quality than the ones coming out of Fremont, California. It's like Tesla finally figured out how to make cars properly - they just haven't applied that knowledge everywhere yet.

But here's the thing: panel gaps are still a lottery game with Tesla. Sometimes you get a perfectly aligned car, sometimes you don't. The Fremont factory, in particular, still seems to struggle with consistency. And the Cybertruck? Early owners have been posting all sorts of alignment issues online, proving that Tesla's still working out the kinks on new models.

The Silicon Valley Problem

Part of Tesla's issue is that they're basically a tech company trying to build cars. Traditional automakers have had over a century to perfect their manufacturing processes, while Tesla has been winging it with a "move fast and break things" mentality. That works great for software, not so much for metal panels that need to line up perfectly.

Tesla's newer factories in Berlin and Texas are supposed to be better, with fancy new techniques like giant casting machines that make fewer parts to mess up. They've also got more control over their supply chain than most automakers. But at the end of the day, getting panels to align properly still comes down to good old-fashioned quality control - something Tesla is still learning.

The Bottom Line

So has Tesla fixed their panel gap problem? Sort of. They're definitely better than they used to be, but it's still hit-or-miss depending on which factory built your car and when. The Shanghai cars are solid, the newer factories show promise, but Fremont is still churning out some questionable builds.

Tesla panel gaps have become such a meme that people expect them at this point. The company's working on it, but until they get their quality control dialed in across all their factories, buying a Tesla will still feel a bit like playing panel gap roulette.