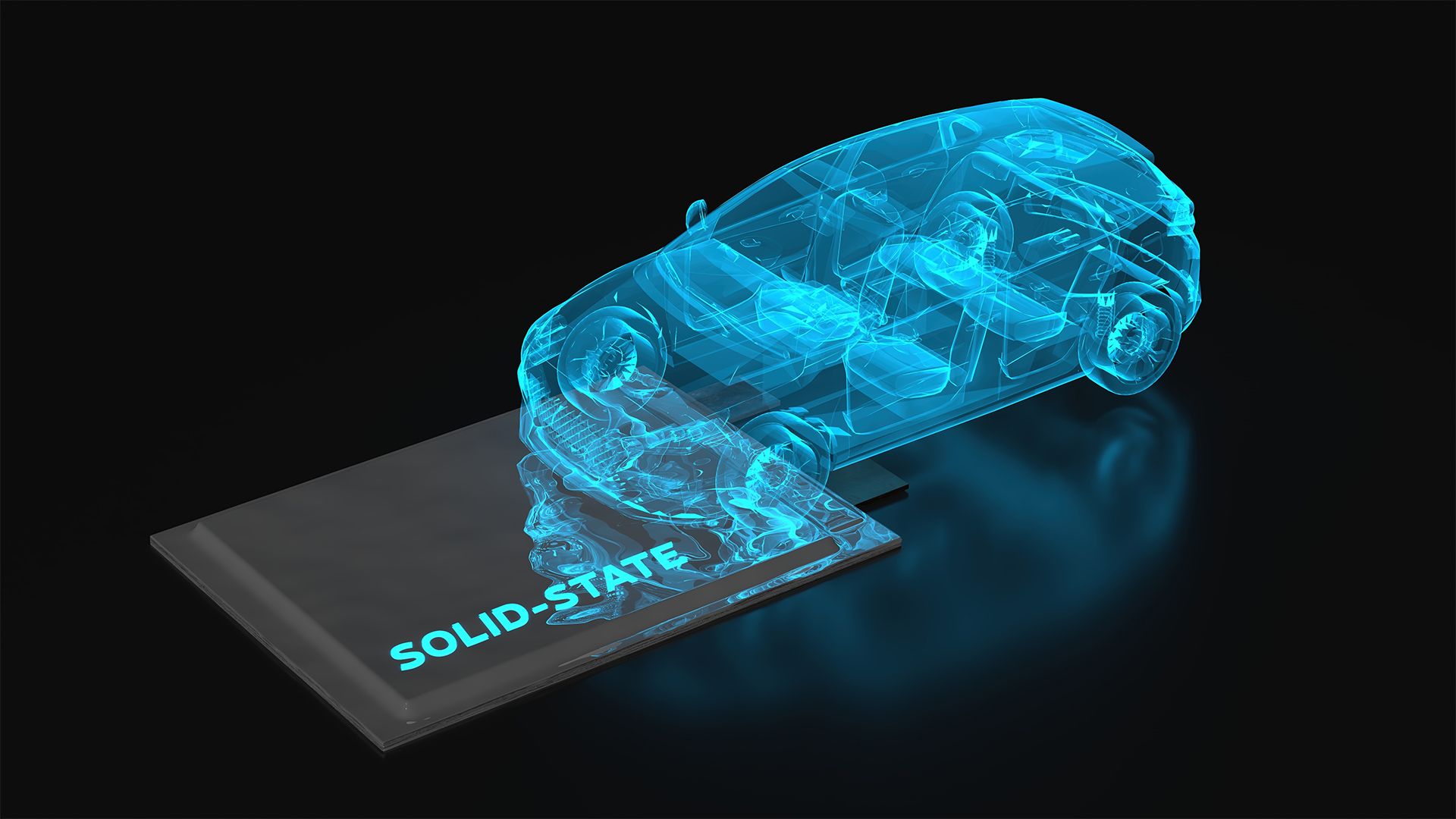

Solid-State Batteries: The Future of EVs?

by AutoExpert | 3 March, 2025

Let's be honest – battery tech has been moving at a snail's pace. Since lithium-ion batteries hit the scene about 30 years ago, improvements have been pretty incremental. Sure, costs drop about 8% yearly thanks to tweaked chemistries, better manufacturing, and scaling up production, but nothing revolutionary has happened... until now, maybe.

The Battery Holy Grail

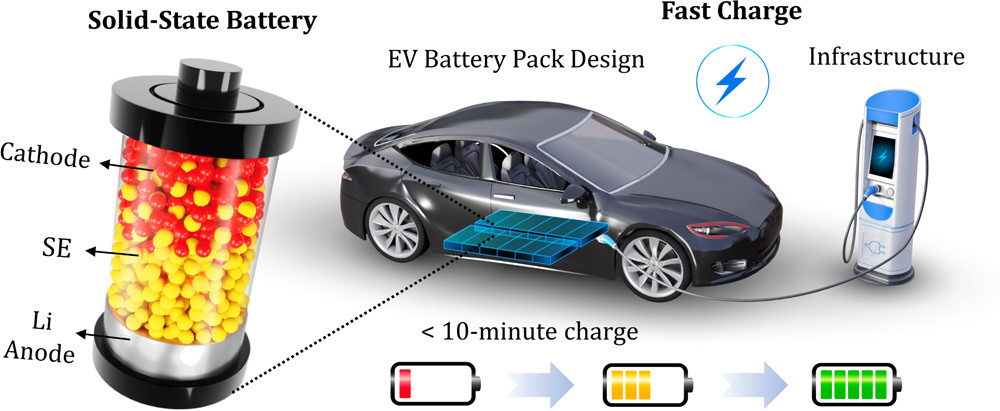

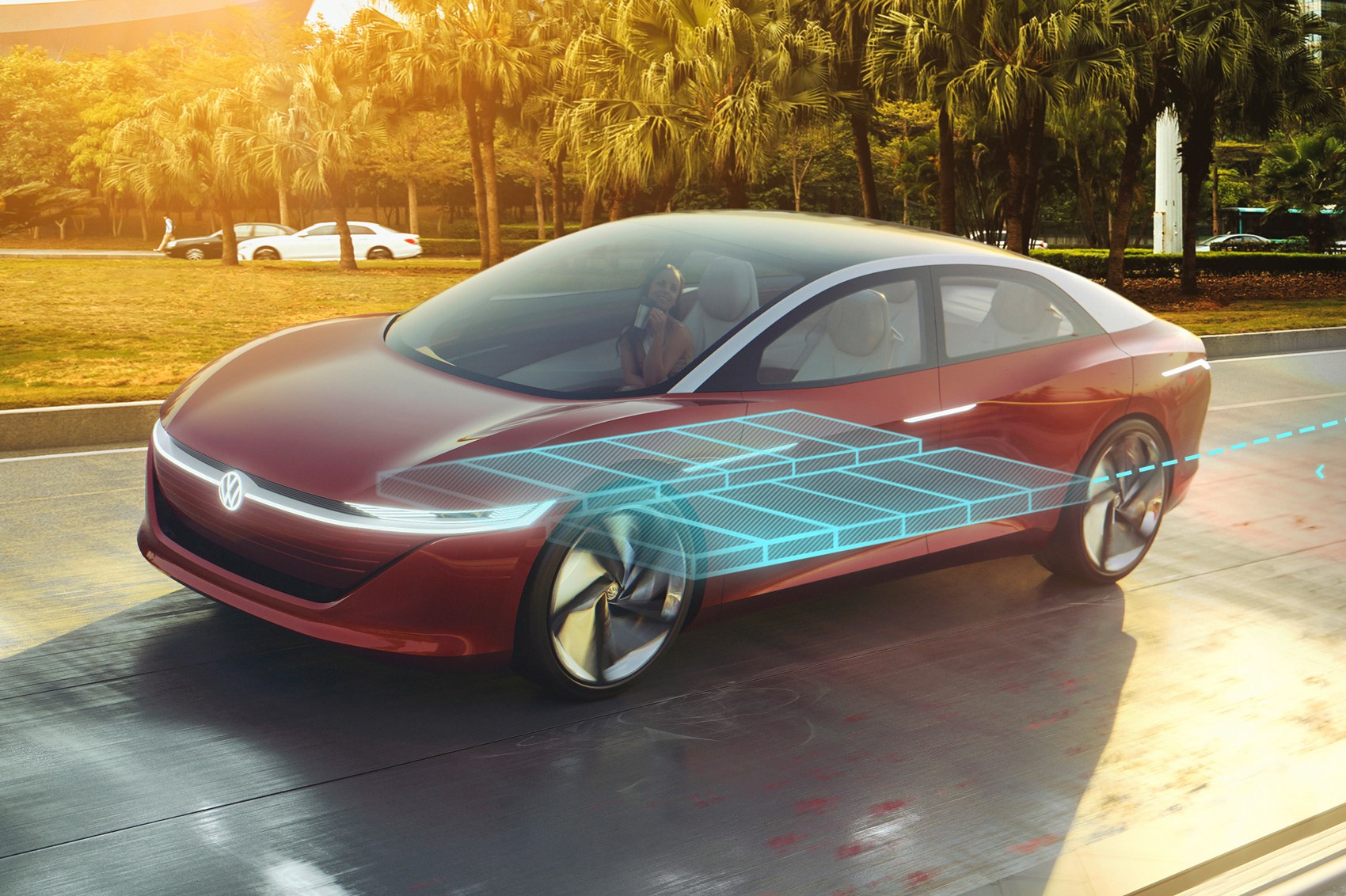

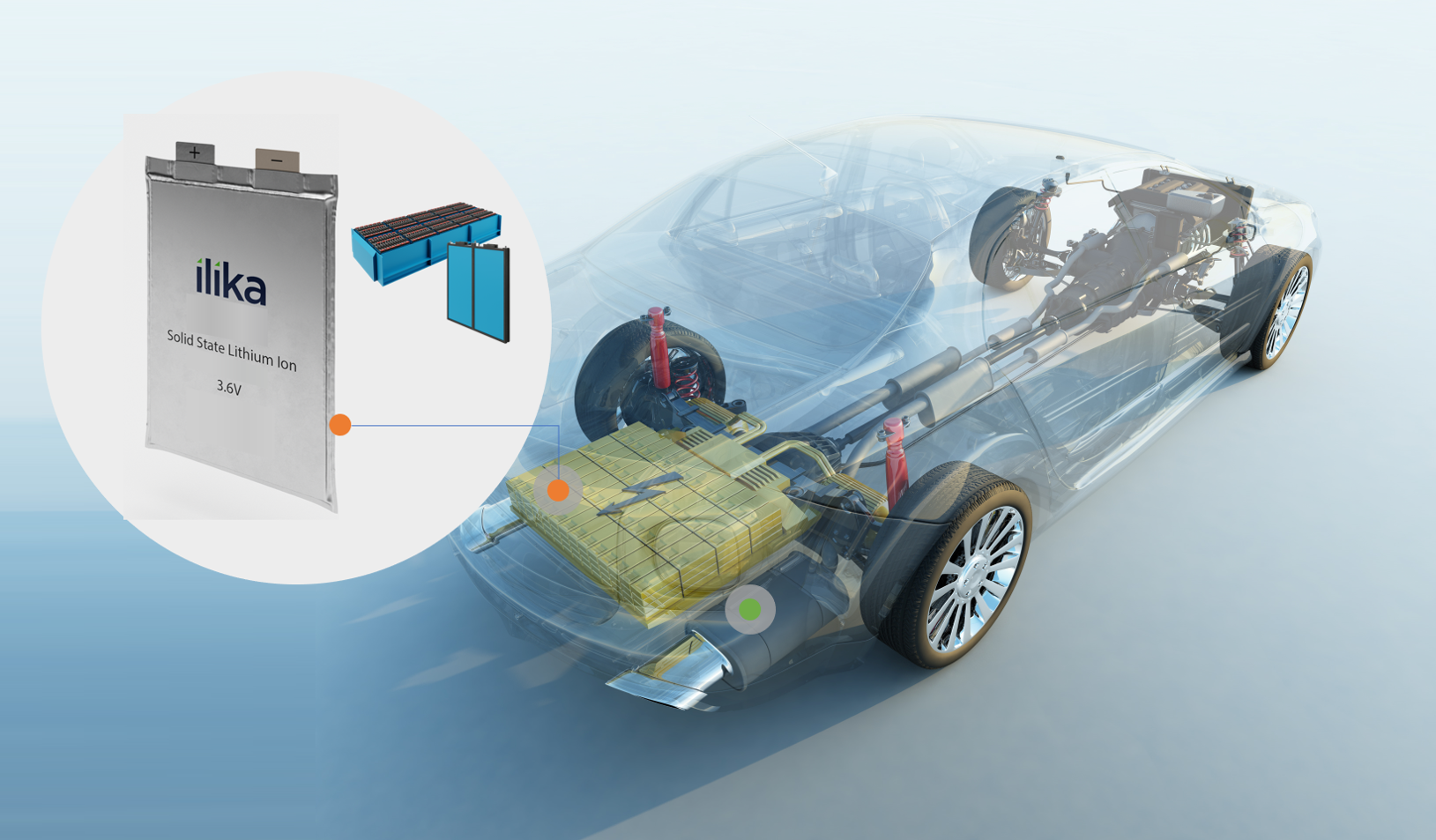

Battery engineers worldwide have been chasing solid-state cells like they're the Holy Grail of energy storage. And for good reason! They promise better energy density (more range), faster charging, and improved safety compared to today's batteries with liquid electrolytes. Some designs even ditch the graphite anodes entirely – which is a big deal since China currently controls that entire supply chain.

How much better are we talking? Toyota's been pretty vocal about their battery plans, claiming their solid-state tech could boost range by nearly 70% and slash fast-charging times from 30 minutes down to just 10 minutes! (Though let's be real – range claims always depend on the vehicle's weight, aerodynamics, and other factors.)

Companies have poured tens of billions into R&D over the last 15 years, and now it looks like we might be getting somewhere. Carmakers across the globe are announcing pilots, prototypes, and breakthroughs in solid-state technology. Expect this pace to pick up in the coming years.

What Actually Makes a Battery "Solid State"?

Here's where things get a bit murky. "Solid state" has become such a buzzword that it's worth understanding what it actually means. The problem? According to Haresh Kamath, who used to design spacecraft batteries at Lockheed Martin, "there is no broad agreement on the definition of 'solid state.'" (He now directs energy storage research at EPRI, an independent research organization for the U.S. electric utility industry.)

So take any solid-state claims with a grain of salt until you dig into the details.

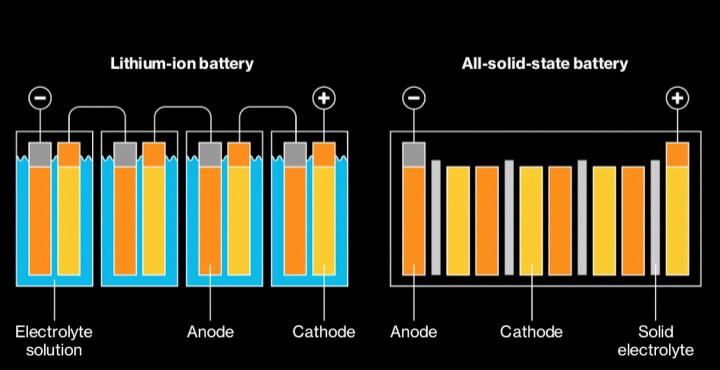

Generally speaking, "solid state" means using a solid material both as the separator (keeping the anode and cathode from touching) and as the medium for electrons to flow through during charging and discharging. Today's batteries use a flammable organic liquid that soaks into the spongy electrode materials – there's no extra liquid sloshing around like in your car's lead-acid starter battery.

The Spectrum of "Solid" Electrolytes

Between today's totally liquid electrolytes and tomorrow's fully solid-state cells, there are several variations:

- Semi-solid electrolytes in "quasi-solid-state" cells (like those lithium-polymer batteries with liquid electrolyte held in a gel)

- High-temperature polymers that conduct ions without being liquid

- Ceramic-coated polymers (also need high operating temps)

- Pure ceramics or glass solid electrolytes (also running hot)

Those last three options allow for using lithium metal anodes paired with either lithiated metal oxide cathodes (using nickel, aluminum, manganese, cobalt, or blends) or iron phosphate cathodes.

Another option? Using lithium metal as a cathode with a solid-state separator enables "anode-free cells" – these replace the traditional anode with a copper current collector where lithium gets deposited during charging. This approach could free us from depending on China-controlled graphite.

But lithium metal comes with its own safety baggage. It's highly flammable at any temperature and reacts violently with moisture or water. Any manufacturer using solid lithium will face intense scrutiny to prove their cells are at least as safe as today's technology – let alone backing up claims of "much greater safety."

The News is Picking Up Steam

Recent headlines show solid-state progress is accelerating:

- In November, Honda announced a test production line for solid-state cells to figure out which materials and processes would work best for high-volume, cost-competitive manufacturing.

- In October, Stellantis revealed that its partner Factorial would test "semi-solid state" cells with a "quasi-solid electrolyte" and lithium anode in a fleet of electric Dodge Charger Daytonas – though not until 2026.

- Chinese automaker Chery claims it's building the world's first all-solid-state battery production line in Wuhu, Anhui Province, with capacity for 1 gigawatt-hour (enough for 100,000 EVs with 100-kWh packs). They're doing this through a joint venture called Anhui Anwa New Energy Technology, formed in 2020 with Chinese battery maker Gotion and various Japanese and Thai partners.

Reality Check: This Stuff is Hard

For every 100 promising battery tests in the lab, maybe one makes it to prototype – and even fewer reach mass production. Toyota learned this lesson the hard way 15 years ago when they couldn't produce the lithium-ion cell they'd chosen for the 2010 Prius and had to fall back on their 15-year-old nickel-metal hydride technology.

Speaking of Toyota – they've been solid-state's biggest cheerleader, even saying EVs won't be suitable for mass adoption until solid-state batteries arrive. But even Toyota has struggled to deliver. They first showed a solid-state prototype way back in December 2010 and spent most of the 2010s promising production by 2020. In late 2023, they pushed that date back to 2027.

Even after new cells enter production, carmakers have to run them through extensive validation before committing to using them in vehicles. Solid-state cells will likely debut at higher prices than conventional lithium-ion cells, so making them cost-competitive will be crucial. Honda claims their solid-state cells will use production methods similar to today's lithium-ion process.

So When Will We Actually See Them?

Siva Sivaram, CEO of solid-state startup QuantumScape, told Reuters in December that he expects "In 2025, at least two companies will announce that they have a solid-state battery. And by the end of 2025, somebody will announce that hey, they are planning on a car with solid-state batteries... [though] they won't tell you when."

He cautiously added, "Solid-state batteries are going to be in high volume [production] in the late part of this decade."

Will China lead the way? "I don't think [pure solid-state cells] will come from China," Sivaram said. (Chinese battery and EV makers would probably disagree.) Eliminating graphite anodes entirely would undercut one of China's key advantages in EV batteries by freeing manufacturers from a material where China controls the supply chain.

The bottom line? All these announcements suggest solid-state cells will indeed make it into North American EVs, possibly before 2030. But I wouldn't bet the farm on any specific year – at least not yet.